NANOFABRICATION AND SURFACE/INTERFACE PHENOMENA AT THE NANOSCALE

People

Sergio Valeri

Guido Paolicelli

Gian Carlo Gazzadi

Nanotribology and functionalized coatings

The present experimental activity aims to study and understand the fundamental processes that rule the tribological phenomena at the nano/micro/macro-scale, and to find new materials and/or procedure to modify and control these tribological phenomena. To this extent, the activity is mainly divided in three topics: (i) deposition of coatings, (ii) surface morphological modifications,(iii) manipulation of nano-object.

Research on these topics is carried on with different fabrication and characterization facilities:

- Focused Ion Beam (FIB), Electron Beam and Optical Lithography, Laser Ablation, Plasma Vapour Deposition (PVD) magnetron sputtering, and

- Atomic/Friction Force Microscopy, Tribometers, Scanning Electron Microscopy (SEM), Profilometry, Auger Electron Spectroscopy (AES), X-ray Photoemission Spectroscopy (XPS), Energy Dispersive X-ray Spectroscopy, X-Ray Diffraction (XRD), FIB cross-sectioning, Auger depth profiling, electromagnetic (e-m) shielding in ultraviolet, infrared and microwave ranges.

(i) Deposition of coatings. Study, development and characterization of PVD-deposited coatings for multiple purposes: anti-corrosion and –wear, self-lubrication, hard coatings, optical and e-m shielding and hydrophobicity. The coatings are produced by RF or DC PVD magnetron sputtering and characterized by surface spectroscopies (XPS and AES), SEM and XRD. Coatings can also be coupled with surface roughness random modification or surface texturing.

Publications

Nanostructured self lubricating CrN-Ag films deposited by Arc Discharge and PVD Magnetron Sputtering

L. Incerti, A. Rota, S. Valeri, A. Miguel, J.A. García, R.J. Rodríguez, and J.Osés

Vacuum 85, 1108 (2011)

Ag Surface Diffusion and Out-of-Bulk Segregation in CrN-Ag Nano-Composite Coatings

L. Incerti, A. Ballestrazzi, A. Rota, E. Gualtieri, and S. Valeri

Journal of Nanosciences and Nanotechnology 11, 9260-9266 (2011)

Thermally-sprayed coatings as interlayers for DLC-based thin films

G. Bolelli, E. Gualtieri, L. Lusvarghi, F. Pighetti Mantini, F. Pitacco, S. Valeri, and H. Volz

J. of Thermal Spray Technology 18, 231 (2009)

Effects of N2 partial pressure on the growth of ChromiumNitridecoatings

F. Capotondi, L. Rettighieri, A. Ballestrazzi, L. Calabri, P. Ferrarini, C. Menozzi, and S. Valeri

La Metallurgia Italiana, luglio-agosto 2007

|

|

The standard deposition procedure has been modified and optimized in order to obtain a random texture of the resultant surface of the film. The graph shows the coefficients of friction vs sliding time of 1 um MoS2 (Molybdenum disulfide) deposited on 1um TiN on steel, measured with a 6 mm ball 100Cr6 counterpart, with different surface textures. The red dashed line indicates the CoF of the system without the coating;all the measurements are liquid lubricants or grease free. As evident all the textured films show lower friction than the uncovered steel, with different trends depending on the properties of each coating.

|

|

|

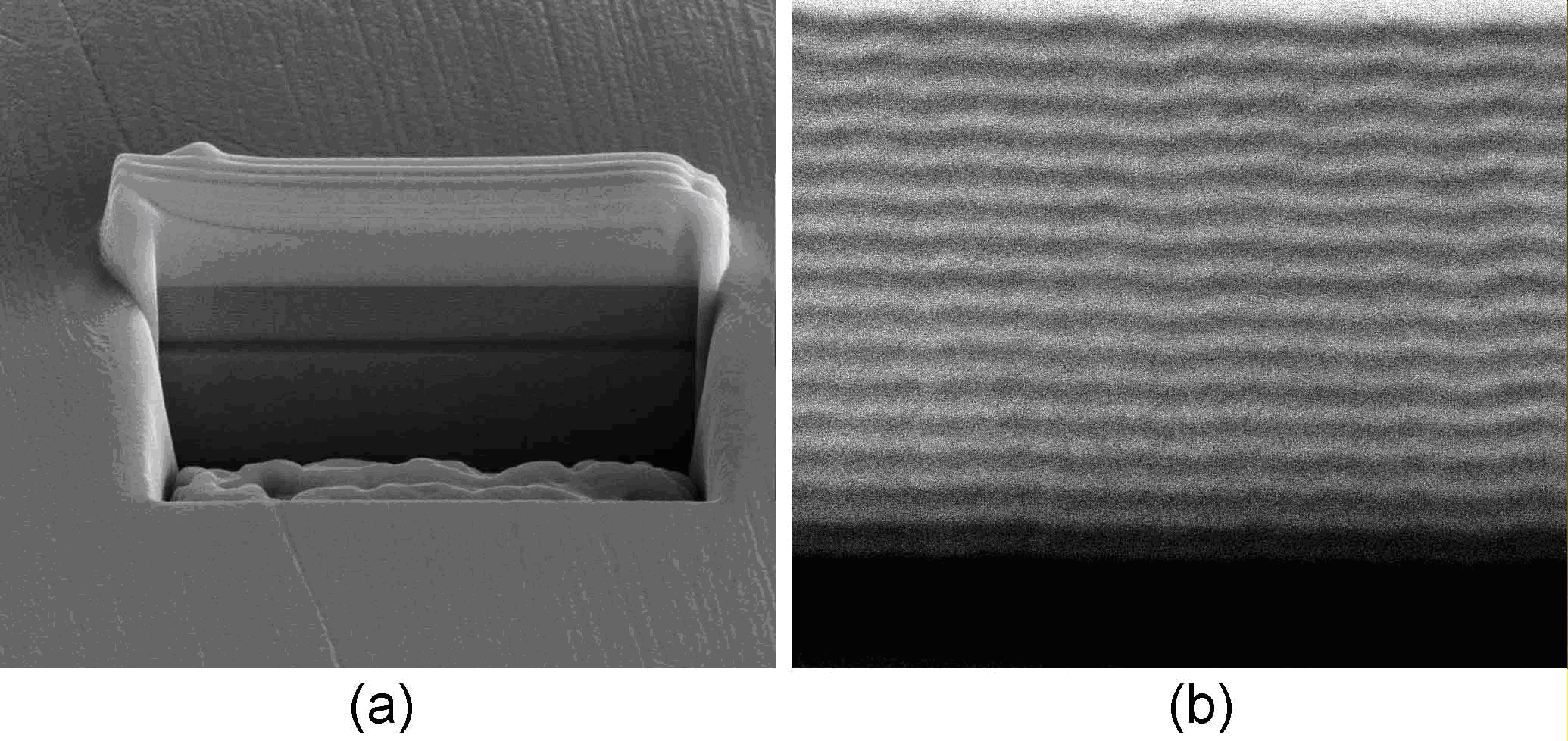

FIB/SEM cross section of a TiN/HfN multilayers. Contact angle measurements reveal that the wettability depends on the thickness of the single layers, with a sharp transition to hydrophobicity at around 60 nm pace.

|

(ii) Surface morphological modifications. The friction properties of two sliding counterparts depend on many parameters, including ambient conditions, temperature, nature of the material and morphology of the surfaces. In particular, the morphology plays an important role, but its influence on the tribology is not univocally determined, and depend on the related scale. We focus on the study of the tribological properties of patterned surfaces, from nano- to macro-scale. The patterning used techniques are scale-dependent: nano-patterns are fabricated by means of FIB and EBL, micro-patterns by means of optical lithography and laser ablation.

|

|

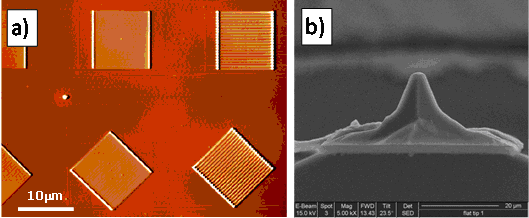

(a) Regular arrays of nano-grooves fabricated by means of FIB patterning on SiO2-Si(001). Tribological properties are investigated for different geometrical parameters.

(b) FIB-modified Si tip used for tribological tests by AFM: the extended contact area enables to estimate the integrated effect of the nano-structures on the tribological properties of the surface. It also induces a hydrophobic character to the Si surface, reducing adhesion and friction. This effect depends on the separation among the nanostructures and almost disappears for pitches above 500 nm.

|

|

|

Regular array of microcavities generated by laser ablation reduces friction and wear of lubricated sliding steel surfaces. This thanks to the enhancement of the hydrodynamic lift-off effect and to the role played by the microcavities as lubricant reservoir and debris pockets. The stribeck curves show how micropatterning reduces friction and shifts the boundary lubrication regime toward lower Stribeck numbers, namely to more severe sliding conditions. The effect of patterning depends on the geometry of the artificial texture.

|

Publications

Hydrophobic effect of surface patterning on Si surface

D. Marchetto, A. Rota, L. Calabri, G.C. Gazzadi, C. Menozzi, and S. Valeri

Wear 268, 488-492 (2010)

Characterization and collateral effects of laser texturing

S. Valeri, E. Gualtieri, and A. Borghi

in Encyclopedia of Tribology, essay 01072, Q. Jane Wang & Yip-Wah Chung, Editors.Springer Science+Business Media, LLC, New York, NY 10013-1578.

Increasing nanohardness and reducing friction of nitride steel by surface laser texturing

E. Gualtieri, A. Borghi, L. Calabri, N. Pugno, and S. Valeri

Tribology International 42, 699-705 (2009)

AFM investigation of tribological properties of nano-patternedsiliconsurface

D. Marchetto, A. Rota, L. Calabri, G. C. Gazzadi, C. Menozzi, and S. Valeri

Wear 265, 577-582 (2008)

Tribological effects of surface texuring on nitride steel for automotive engine applications

A. Borghi, E. Gualtieri, D. Marchetto, L. Moretti, and S.Valeri

Wear 265, 1046-1051 (2008)

Role of Roughness Parameters on the Tribology of Randomly Nano-Textured Silicon Surface

E. Gualtieri, N. Pugno, A. Rota, A. Spagni, E. Lepore, and S. Valeri

J. Nanosci. Nanotech. 11, 9244-9250 (2011)

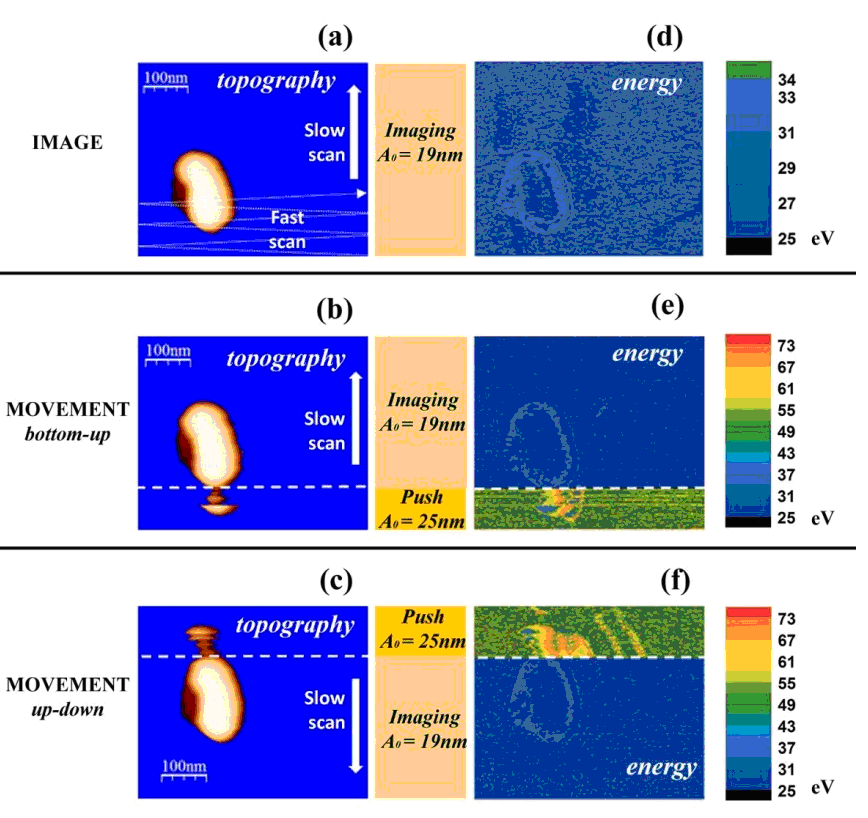

(iii) Manipulation of nano-objects. The interplay between tribology response of nanoobjects and their movements is a relevant scientific topic with interesting outcome in nanotechnology. On the one hand, nanoclusters, which maintain their shape and mass during a forced movement, are ideal nano-contacts and their study may help understanding fundamental nanotribology questions. On the other, the control of elementary nanomovements may be used to optimize engineering bottom–up building processes at the nanoscale. To this end, we recently introduced a novel approach: AFM microscope intapping mode is used to induce detachment and to control the movement of single nanoclusters; the tribology response is then eventually extracted from energy dissipation signal.

Publications in international journals

Sliding onset of nanoclusters: a new AFM based approach

M. Rovatti, G. Paolicelli, A. Vanossi, and S. Valeri

Meccanica (Springer Ed.) 46, 597 (2011)

Controlling single cluster dynamics at the nanoscale

G. Paolicelli, M. Rovatti, A. Vanossi, and S. Valeri

Appl. Phys. Lett. 95, 143121 (2009)

Adhesion detachment and movement of gold nanoclusters induced by dynamic atomic force microscopy

G. Paolicelli, K. Mougin, A. Vanossi, and S. Valeri

J. Phys. Condens. Matter. 20, 354011 (2008)

Controlled manipulation of thiol-functionalised gold nanoparticles on Si(100) by dynamic force microscopy

G. Paolicelli, K. Mougin, A. Vanossi, and S. Valeri

Journal of Physics: Conference Series 100, 052008 (2008)

Single cluster AFM manipulation: a specialized tool to explore and control nanotribology effects

G. Paolicelli, M. Rovatti, and S. Valeri

in B. Bhushan (ed.) “Scanning Probe Microscopy in Nanoscience and Nanotechnology Vol.2” Springer, Berlin (2011)

|

|

(a) Topographic image of a gold nano-cluster deposited on a freshly cleaved HOPG graphite (the blue plane is a 10 nm cut-off introduced for graphical reason). The corresponding energy dissipation signal is shown on panel (d).

(b) The tip oscillation amplitude (A0) is increased at the beginning of the scan (bottom) by increasing the piezo amplitude oscillations (the amplitude set point is held fixed along the whole scan). As a consequence the energy dissipation signal increases (panel (e)), and the particle detachment is induced. After few scan lines A0 is reduced to the optimized value for imaging and the particle movement is stopped, then the scan continues as a normal image acquisition.

(c) and (f): the same procedure as above is repeated while scanning the image from the top. This sequence demonstrates how controlled cluster movement along the AFM slow scan direction are easily obtained with accuracy in a 10 nm range.

|